-

Whatsapp +86 13526654721

-

Email: sales@carmatrolls.com

-

Address: AUX Industrial Park, Shangjie District, Zhengzhou City, Henan Province, China

-

Whatsapp +86 13526654721

-

Email: sales@carmatrolls.com

-

Address: AUX Industrial Park, Shangjie District, Zhengzhou City, Henan Province, China

Perfecting Car Mat Heel Pads: Why High-Frequency Welding Beats Stitching

What makes high-frequency welding superior to traditional stitching for attaching automotive car mat heel pads?

High-frequency welding creates a hermetic, waterproof seal by fusing materials at a molecular level, effectively eliminating the water leakage and durability issues inherent in stitched seams. This technology offers a seamless aesthetic finish, superior bond strength, and significant long-term manufacturing ROI through reduced labor costs and drastic reductions in material waste.

The Critical Flaws of Traditional Heel Pad Attachment

Why is traditional stitching often considered the weakest link in modern car mat manufacturing?

Stitching inherently compromises the structural integrity of the car mat by puncturing the material with thousands of needle holes. These permanent perforations destroy the waterproof barrier of materials like PVC or rubber, allowing moisture to penetrate the vehicle floor, while the exposed threads rapidly degrade under the constant abrasion of the driver’s heel.

Water Leakage Risks in Stitched Seams

The fundamental problem with sewing is mechanical perforation. To attach a heel pad, a needle must physically pierce both the pad and the base mat material. In the automotive accessory industry, we call this “compromising the substrate.”

Even with tight stitching, these needle holes create a direct pathway for liquids. When a driver enters a vehicle with wet or snowy shoes, water accumulates on the heel pad. Through a process called capillary action, this water wicks down the threads and passes through the needle holes.

Once that barrier is breached, the moisture reaches the original car carpeting underneath the mat. This leads to several hidden issues that the car owner may not notice until it is too late:

- Mold and Mildew Growth: Trapped moisture under the mat creates a breeding ground for fungi.

- Corrosion Potential: In older vehicles, persistent dampness can eventually reach the metal floor pan.

- Odor: Stagnant water in the carpet fibers causes a persistent, musty smell inside the cabin.

To use an industry analogy, a stitched car mat functions like a convertible soft top that has been sewn without waterproof seam tape—it may look secure, but under liquid pressure, it will inevitably leak.

Durability Issues and Thread Wear Over Time

The heel pad is the highest-wear zone of any car mat. It endures constant pressure, friction, and pivoting movement from the driver’s right foot. In a stitched assembly, the thread itself becomes the primary point of failure.

In traditional sewing, the thread sits “proud” (slightly raised) above the surface of the heel pad. This means the thread takes the brunt of the abrasion every time the driver moves their foot between the gas and brake pedals.

The Cycle of Failure

- Surface Abrasion: The driver’s heel rubs against the exposed thread top.

- Fiber Fraying: The thread begins to fray and weaken.

- Snap and Unravel: Once a single stitch snaps, the tension releases, causing adjacent stitches to loosen.

- Pad Detachment: The heel pad eventually curls up at the edges or completely detaches.

This is not just a quality issue; it is a safety hazard. A detached or curling heel pad can physically obstruct the brake or accelerator pedal. In the automotive interior industry, pedal interference is a critical failure mode that manufacturers must avoid at all costs.

Aesthetics and Surface Irregularities in Sewn Mats

Beyond performance, stitching introduces visual inconsistencies that lower the perceived value of the product. Achieving a perfectly straight, uniform stitch line on thick, multi-layered materials (like PVC backing plus a carpet top) is mechanically difficult.

Industrial sewing machines often struggle with “material feed” on rubbery textures. This leads to puckering, where the material bunches up around the needle hole, creating a wavy or wrinkled appearance.

Then there’s the visual aftermath. On premium PVC or leatherette mats, needle holes appear as permanent scars on the surface. If a mistake is made during production and the thread is removed to be re-sewn, the original holes remain, ruining the piece. This results in a product that looks assembled rather than engineered, lacking the sleek, integrated finish found in high-end OEM (Original Equipment Manufacturer) automotive interiors.

How High-Frequency Welding Transforms Heel Pad Quality

So, how do we fix a process that relies on punching holes in a waterproof material?

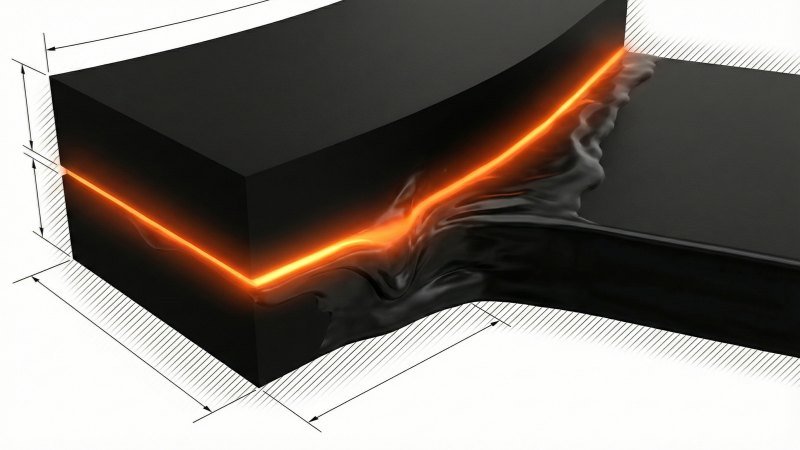

High-frequency (HF) welding fundamentally changes the manufacturing process by replacing mechanical fasteners with energy-based bonding. This shift addresses the core limitations of sewing by using electromagnetic energy to fuse thermoplastic materials together at a molecular level. The result is a hermetically sealed, waterproof bond that is physically stronger than the materials themselves.

Creating a Watertight Hermetic Seal

The most immediate quality upgrade HF welding offers is the creation of a hermetic seal. Unlike sewing, which punches holes, or gluing, which adds a third layer of material, welding merges the heel pad and the base mat into a single unit.

During the process, the HF welding machine applies high-frequency energy (typically 27.12 MHz) to the materials. This energy excites the molecules within the PVC or PU materials, causing them to generate heat internally. Under the pressure of the welding die, the materials melt and flow into each other.

When they cool, they are no longer two separate sheets; they are one continuous piece of plastic. This creates a barrier that is 100% waterproof.

Think of this like joining two pieces of sheet metal in an auto body shop. If you use rivets, there are gaps where moisture can enter and cause rust. If you spot weld the metal, the two pieces become physically one, creating a solid, impenetrable joint. For a car mat, this means that even if a driver spills a full cup of coffee on the heel pad, the liquid cannot pass through to the carpet below.

Achieving a Seamless and Flush Aesthetic Finish

In the automotive interior market, visual appeal is just as important as function. High-frequency welding allows manufacturers to achieve a “flush” finish that looks engineered rather than assembled.

Because the welding die presses down into the material while it is soft and pliable, the edges of the heel pad can be sunk slightly into the base mat. This eliminates the raised, rough edges often seen on stitched pads. The result is a smooth transition between the pad and the mat, similar to the integrated dashboard components found in luxury vehicles.

Better yet, this process allows for “tear-seal” capabilities or smooth-edge finishing without extra labor. The tooling creates a clean, defined border instantly. There are no loose threads to trim and no needle puckering to smooth out.

| Feature | Stitched Appearance | HF Welded Appearance |

|---|---|---|

| Edge Profile | Raised, often curling upward | Flush, embedded into base |

| Surface Texture | Puckered around needle holes | Smooth and consistent |

| Uniformity | Varies by operator skill | Identical every cycle |

| Visual Defects | Visible holes, loose threads | None (seamless integration) |

Enhanced Bond Strength via Molecular Fusion

The durability of a welded heel pad is superior because the bond relies on molecular fusion rather than mechanical friction.

In a stitched mat, the strength of the hold depends entirely on the tensile strength of the thread. If the thread is cut, the hold is lost. In an HF welded mat, the bond extends across the entire surface area of the weld line, or even the entire face of the pad if a full-face die is used.

Industry pull-tests often show that a proper HF weld is stronger than the material itself. This means that if you try to forcefully rip the heel pad off, the PVC material will likely tear before the welded seam separates. This is known in the manufacturing industry as “substrate failure,” and it is the gold standard for bond quality.

This molecular bond is also highly resistant to environmental stressors. It does not weaken when exposed to the high temperatures of a parked car in summer or the freezing cold of winter. Adhesives (glues) often crystallize and fail in freezing temperatures or soften and slide in extreme heat. Molecular fusion remains stable, ensuring the heel pad stays perfectly in place for the life of the mat.

Key Machine Features for Optimal Heel Pad Production

What specific technical specifications define a high-frequency welding machine capable of producing professional-grade car mat heel pads?

To ensure optimal production quality, machines must possess adequate power output (typically 8KW to 15KW) to penetrate thick material stacks, high-sensitivity anti-spark systems to protect expensive tooling, and precision alignment mechanisms for accurate logo placement. These three features directly dictate the structural integrity of the weld and the visual consistency of the final product.

Power Output Requirements for Different Material Thicknesses

The total thickness and surface area of the heel pad determine the necessary power output. Unlike sewing, where the machine’s power relates to needle piercing force, High-Frequency (HF) welding power relates to the volume of material that must be heated simultaneously.

Car mats are dense. A typical assembly includes the base carpet, a waterproof backing (often nibbed PVC), and the heel pad itself. This stack can easily exceed 5mm to 10mm in total thickness. A standard 4KW machine, often used for thin packaging or raincoats, lacks the energy density to excite the molecules throughout this thick stack efficiently.

If the power is too low, you risk a “cold weld.” In this scenario, the surface might look fused, but the internal bond is weak and will peel apart under stress.

For reliable automotive production, a higher kilowatt rating is essential.

| Material Stack Thickness | Recommended Power Output range* | Application Scenario |

|---|---|---|

| Thin (Under 3mm) | 5KW – 8KW | Lightweight universal mats |

| Standard (3mm – 8mm) | 8KW – 10KW | Standard sedan/SUV mats |

| Heavy Duty (8mm+) | 12KW – 25KW | Luxury thick pile or truck mats |

Please note: Power requirements can vary significantly based on the specific material composition (e.g., pure PVC vs. recycled mixes) and the surface area of the welding die.

It’s the same principle as a hydraulic press in a metal stamping workshop. If you are stamping thin sheet metal, a 10-ton press is sufficient. However, if you attempt to stamp a thick steel plate with that same press, the metal will not form correctly because the force is inadequate. Similarly, insufficient HF power fails to generate the necessary molecular friction deep within the car mat.

Importance of Anti-Spark Systems for Mold Protection

In high-frequency welding, an electrical arc (spark) is the greatest enemy of your tooling. A spark occurs when the high-voltage energy finds a path of least resistance—often due to dust, humidity, or carbon in the material—and jumps between the electrode (the upper die) and the bedplate.

Without protection, this arc functions like a miniature lightning strike. It instantly burns a pit into the brass or aluminum welding die.

Since heel pad molds are custom-machined to fit specific mat contours and textures, they are expensive assets. A single deep burn mark can render a mold useless, as that mark will transfer onto every subsequent heel pad produced.

High-sensitivity anti-spark systems (often referred to in the industry as PL5557 or similar thyratron protection circuits) are mandatory for this application. These systems detect the current imbalance that precedes a spark.

- Detection: The system senses an anomaly in the electrical flow.

- Cut-off: It cuts off the high-frequency power in a fraction of a second (microseconds).

- Result: The arc is extinguished before it can damage the mold or burn through the car mat.

This is comparable to a fast-acting electronic fuse protecting sensitive circuit boards. Just as a fuse blows instantly to prevent a power surge from destroying expensive equipment, the anti-spark system cuts power instantly to prevent the arc from “pitting” the mold.

Precision Positioning for Consistent Logo Embossing

Many car mat heel pads feature embossed logos, anti-slip tread patterns, or decorative borders. These design elements are created by the welding die itself. Therefore, the alignment of the machine is critical.

If the welding head descends even a few millimeters off-center, the logo will look crooked relative to the mat’s edge. In the premium automotive aftermarket, visual symmetry is a primary indicator of quality.

Optimal machines for this task utilize robust mechanical limits and precision guide rails.

- Four-Post Gantries: Machines with a four-post structure ensure the welding platen descends perfectly parallel to the bed. This ensures even pressure across the entire heel pad, preventing “weak spots” on one side of the weld.

- Laser Guides: Some advanced units employ laser crosshairs. Operators line up the mat material with the laser before engaging the cycle, ensuring the heel pad is welded in the exact correct coordinate every time.

In a workshop context, consider the difference between a hand drill and a drill press. A hand drill (manual positioning) allows the bit to wander, creating an angled hole. A drill press (fixed positioning) guarantees the hole is straight and located exactly where intended. For heel pads, rigid machine positioning acts as that drill press, guaranteeing that every logo is centered and every edge is straight.

Selecting the Right HF Welder Configuration

How do you determine whether a turntable system or a sliding tray model is the correct choice for your specific car mat production line?

Selecting the correct High-Frequency (HF) welder configuration depends primarily on production volume and mat size. Turntable machines are engineered for continuous, high-speed output of standard-sized mats, while sliding tray models offer the extended surface area required for large, single-piece floor liners or truck mats.

Turntable Machines for High-Volume Manufacturing

For factories targeting maximum daily output, the automatic turntable (or rotary) machine is the industry standard. This configuration typically features a round table with three or four workstations that rotate around a central axis.

The primary advantage here is concurrent operation. In a standard manufacturing setup, the welding cycle itself takes time (perhaps 5 to 10 seconds). On a single-station machine, the operator must wait for the weld to finish before loading the next mat.

A turntable completely removes this bottleneck. While the machine is welding the heel pad at Station 1, the operator is simultaneously unloading a finished mat at Station 2 and loading raw materials at Station 3. This is similar to a rotary indexing table used in automated CNC machining, where loading and processing happen at the same time to maximize spindle uptime.

- Speed: Increases production capacity by 50% to 100% compared to stationary machines.

- Labor Efficiency: One operator can keep the machine running continuously without pause.

- Application: Ideal for standard 4-piece car mat sets (driver, passenger, rear) where the mats fit within standard dimensions (usually under 600mm x 800mm).

Sliding Tray Models for Large Format Mats

Not all car mats fit on a rotating table. Modern vehicle trends, particularly with SUVs and trucks, favor “full-coverage” floor liners. These are often large, single-piece units that cover the entire rear floor or cargo area.

For these oversized products, a Sliding Tray (or Shuttle) HF Welder is the superior choice. In this configuration, the bedplate slides out towards the operator for loading, then slides back under the welding head.

The key benefit is unrestricted space. Unlike a rotary table, which is limited by the pie-slice shape of each station, a sliding tray offers a large, rectangular work area. This allows you to position a large cargo mat flat without folding or bending it, which ensures the heel pad is welded perfectly straight.

Think of this like a flatbed CNC router versus a small enclosed mill. The flatbed (sliding tray) allows you to process large sheets of material that simply wouldn’t fit inside the enclosure of a smaller machine.

| Feature | Turntable (Rotary) | Sliding Tray (Shuttle) |

|---|---|---|

| Primary Goal | High Speed / Volume | Large Size / Flexibility |

| Material Handling | Standard Mats (Driver/Passenger) | Full Floor Liners / Trunk Mats |

| Cycle Workflow | Load while Welding | Load then Weld (Sequential) |

| Footprint | Requires clearance for rotation | Long, rectangular footprint |

Custom Mold Design Considerations for PVC and PU Mats

Selecting the machine is only half the battle; the welding die (mold) serves as the actual interface with the product. When “perfecting” the heel pad, the mold design must align with the specific material properties of PVC (Polyvinyl Chloride) or PU (Polyurethane).

Material Conductivity and Heat Distribution:

PVC and PU react differently to HF energy. A mold designed for PVC usually requires a sharp, defined edge to create a “tear-seal” (where excess material can be torn away cleanly). However, PU often requires a broader sealing face to ensure the bond holds without cutting through the thinner material layers.

Brass vs. Aluminum Tooling:

- Brass: Most common for high-quality heel pads. It heats up quickly and maintains a stable temperature. It is durable and allows for very fine engraving of logos or anti-slip textures.

- Aluminum: Cheaper and lighter, but less durable. It is often used for short runs or prototyping.

Pressure Balancing:

The mold must be designed with “stops” or limiters. If the mold presses too deep, it will thin out the heel pad material, creating a weak spot that wears out quickly. If it is too shallow, the weld will fail. A professional mold maker will machine “stand-offs” into the tool to physically prevent it from crushing the mat, regardless of the machine’s pressure setting.

Calculating the ROI of Upgrading to HF Technology

Is the financial investment in high-frequency welding equipment justified by the long-term savings in car mat manufacturing?

The Return on Investment (ROI) for High-Frequency (HF) welding technology is typically realized within 12 to 18 months through drastic reductions in material scrap and labor expenses. By replacing manual stitching with automated bonding, manufacturers eliminate costly consumables and lower per-unit production costs by approximately 20% to 30%, depending on total output volume.

Reducing Material Waste and Rejection Rates

One of the largest hidden costs in traditional car mat production is “scrap” caused by irreversible errors.

In a sewing operation, the heel pad is often the final step in the assembly process. At this stage, the base mat has already been cut, edged, and shaped. It carries the full value of the raw material.

If a sewing operator makes a mistake—such as a crooked stitch line, a skipped stitch, or a needle break—the damage is permanent. You cannot simply remove the thread and try again because the needle holes remain visible in the PVC or leatherette surface. The entire driver’s side mat must be discarded.

Industry data suggests that manual sewing lines often experience rejection rates between 3% and 5% due to human error.

High-Frequency (HF) welding virtually eliminates this variable. The process uses a fixed metal die (mold). Once the machine is set up and aligned, the die strikes the exact same position every single time. It is a binary process: if the machine cycles, the weld is correct.

Key Sources of Waste Reduction:

- No Needle Damage: Since there are no needles, there are no accidental punctures to ruin the waterproof backing.

- Consistent Alignment: Mechanical guides ensure the pad is never attached crookedly, removing the need for visual estimation.

- Recoverable Misalignment: If an operator places a mat incorrectly before the welding cycle starts, they can simply move it. In sewing, once the needle drops, the piece is committed.

Look at it like a stamping press in a metal fabrication shop. Once the die is aligned, the press produces thousands of identical parts with near-zero variance. Sewing is more like manual drilling; a single slip of the hand ruins the workpiece.

Lowering Long-Term Labor Costs compared to Sewing

Labor is often the most expensive line item in Western and many Asian manufacturing hubs. HF welding shifts the production model from “skilled craftsmanship” to “machine tending.”

The Skill Gap:

Sewing a heavy, rubber-backed car mat requires a skilled operator. They must physically wrestle with the heavy material, rotating it smoothly to follow the curve of the heel pad while managing pedal speed. Training a proficient industrial sewer can take three to six months. Consequently, these workers command higher wages.

In contrast, operating an HF welding machine requires minimal skill. The operator simply places the material against a stop and presses a button. The machine handles the pressure, time, and energy application. A new employee can be trained to run an HF welder effectively in less than one day.

Cycle Time Efficiency:

Beyond wages, the speed of production is vastly different.

- Sewing Cycle: An operator might take 45 to 60 seconds to position, sew, turn, and trim a heel pad.

- Welding Cycle: An automated turntable machine can complete a weld cycle in 5 to 8 seconds.

This means a single HF welding station can often match the output of four or five manual sewing stations. This allows factory owners to consolidate their workforce or reassign skilled sewers to more complex tasks that machines cannot do, such as binding complicated edges.

| Cost Factor | Manual Stitching | High-Frequency Welding |

|---|---|---|

| Operator Skill Required | High (Months of training) | Low (Days of training) |

| Cycle Time per Piece | 45 – 60 Seconds | 5 – 10 Seconds |

| Consumables | Thread, Needles, Bobbins, Oil | None (Electricity only) |

| Defect Rate | Variable (Human dependent) | Near Zero (Machine dependent) |

Please note: While labor savings are significant, manufacturers should account for the higher upfront energy consumption of HF machines (15KW+) compared to sewing motors (0.5KW) when calculating total operational costs.

Conclusion

Switching from stitching to high-frequency welding represents a fundamental shift in how car mat heel pads are perfected. By addressing the critical flaws of water leakage, thread wear, and aesthetic inconsistency, HF technology offers a clearly superior product for the end consumer.

For the manufacturer, the advantages are equally compelling. While the initial investment in machinery and tooling is higher than sewing, the long-term gains in production speed, reduced waste, and lower labor dependency provide a robust return on investment. In a market where buyers demand durability and premium finishes, high-frequency welding is no longer just an option; it is the standard for modern automotive interior production.