-

Whatsapp +86 13526654721

-

Email: sales@carmatrolls.com

-

Address: AUX Industrial Park, Shangjie District, Zhengzhou City, Henan Province, China

-

Whatsapp +86 13526654721

-

Email: sales@carmatrolls.com

-

Address: AUX Industrial Park, Shangjie District, Zhengzhou City, Henan Province, China

Car Mat Anti-Slip Backing Comparison: Burr vs. Spikes vs. Maxpider

What is the most effective and efficient anti-slip backing for modern car mat manufacturing: Burr, Spikes, or Maxpider?

Burr and Maxpider backings offer superior manufacturing efficiency through hot-press lamination and reduce shipping costs due to their lightweight nature, whereas traditional rubber spikes require energy-intensive injection molding. While spikes rely on heavy mass for grip, modern fiber-based backings utilize mechanical interlocking to provide enhanced safety without damaging OEM carpeting.

Composition and Material Characteristics

Traditional rubber spikes rely on heavy, injection-molded PVC nibs that use weight and penetration to anchor the mat, whereas Maxpider utilizes a patented, semi-rigid fiber grid designed to interlock with carpet loops without damage. Compare that to burr and felt backings, which feature a lightweight, non-woven polyester textile structure creating surface friction similar to hook-and-loop fasteners.

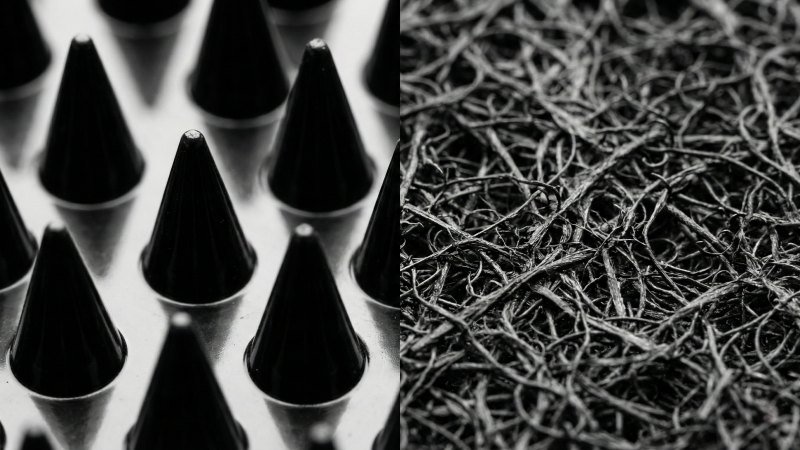

Physical structure of traditional injection-molded rubber spikes

The structure of a traditional anti-slip backing is defined by its density and protrusion. These backings, commonly referred to as “nibs” or “cleats,” consist of a solid, continuous sheet of material, typically Polyvinyl Chloride (PVC) or Thermoplastic Rubber (TPR). The primary mechanism here is physical penetration.

On the underside, rows of conical or cylindrical spikes protrude outward. These spikes are integral to the mat’s main body. They are not a separate layer added later; rather, they form the bottom surface of the molded material itself.

- Material Density: The PVC used is dense and heavy. This weight helps push the spikes down into the vehicle’s floor carpet.

- Spike Geometry: The nibs usually range from 3mm to 5mm in height. They are stiff and blunt.

This structure operates similarly to the tread blocks on an off-road tire, which require deep channels and significant mass to dig into loose terrain. Just as a tire tread needs a thick rubber base to prevent tearing, rubber spikes require a significant base thickness to maintain integrity. If the base layer is too thin, the spikes will shear off during mold ejection or use. The result? A heavy, bulky product that feels outdated compared to modern composites.

Note on Specifications: Spike density (nibs per square inch) and height can vary significantly based on the specific mold design and PVC formulation. Always verify the exact durometer (hardness) specs with your raw material supplier to ensure the spikes are rigid enough to grip but not sharp enough to damage carpets.

Proprietary fiber interlocking technology of Maxpider

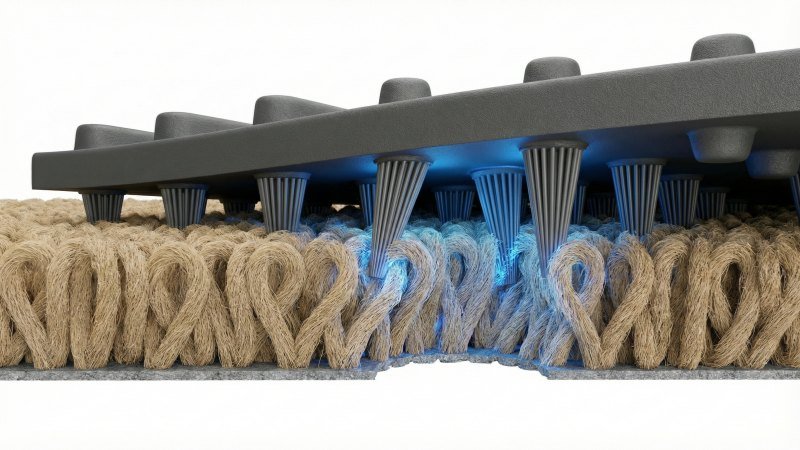

Maxpider technology represents a shift from “heavy weight” to “smart grip.” The composition here is entirely different from the solid block of PVC found in traditional mats. Maxpider is a distinct textile layer, not a molded rubber.

The structure consists of a mesh fabric base. Embedded into this mesh are thousands of short, stiff fibers. These are not soft threads; they are semi-rigid. Under a microscope, these fibers look like tiny, angled hooks or stiff bristles.

- Multi-layer Integration: Unlike rubber mats, Maxpider backing is almost always part of a composite structure. It is the bottom layer of a “sandwich,” usually fused to an XPE foam middle layer and a TPR top layer.

- The “Kagu” Texture: The fibers are arranged in a specific pattern. This pattern allows them to grab the loop pile of the vehicle’s carpet without penetrating deep into the backing.

Because it is a textile mesh, the Maxpider backing is extremely thin compared to PVC spikes. It adds grip without adding bulk. The fibers work by lateral resistance. When the mat tries to slide sideways, the stiff fibers catch against the carpet loops instantly. This creates a high-friction bond that uses geometry, not weight, to stay in place.

Structural advantages of non-woven burr and felt backings

Burr and felt backings (often called “Anti-Skid” or “Magic Claw” in industry terms) offer a middle ground. The composition here is typically non-woven Polyester (PET) or Polypropylene (PP) fibers.

The structure resembles a chaotic, tangled web of fibers. Unlike the organized grid of Maxpider, burr backing is a needle-punched or scrape-coated textile. It looks and feels somewhat like the “loop” side of a standard Velcro fastener, but with a rougher texture designed specifically for automotive applications.

Key Compositional Features:

- Porosity: The material is breathable and porous. This allows for easier lamination to TPE or TPO layers during production compared to solid rubber.

- Flexibility: The fibrous structure is soft and pliable. It conforms completely to the contours of the floor pan.

The primary structural advantage is the specific surface area. Because the backing is made of thousands of micro-fibers, it creates massive amounts of surface contact with the OEM carpet. It does not rely on stiff hooks (Maxpider) or heavy spikes (PVC). Instead, it relies on the coefficient of friction generated by the rough textile against the carpet pile.

This material is exceptionally lightweight. For manufacturers, this means the backing layer adds almost zero perceptible weight to the final product.

| Feature | Rubber Spikes (Nibs) | Maxpider (Patented) | Burr / Felt / Anti-Skid |

|---|---|---|---|

| Base Material | Solid PVC / TPR | Nylon/PET stiff mesh | Non-woven PET Polyester |

| Grip Mechanism | Weight + Penetration | Mechanical Interlock | High-Friction Surface |

| Physical Profile | Thick, heavy, rigid | Thin, stiff grid | Thin, soft, flexible |

| Structure Type | Monolithic (One piece) | Distinct Laminate Layer | Distinct Laminate Layer |

Manufacturing Process and Lamination Compatibility

Manufacturing requirements diverge significantly based on backing type: traditional rubber spikes demand high-pressure injection molding equipment with extended cooling cycles to form solid nibs, whereas modern burr and Maxpider backings utilize hot-press or flame lamination processes. The latter methods allow for rapid bonding to TPE or TPO layers, enabling continuous roll-to-roll production and significantly reduced cycle times compared to the batch processing required for heavy rubber molds.

Bonding efficiency with TPE, TPO, and hot-press layers

The most critical challenge in modern car mat production is adhesion. You are often trying to stick a fabric (the backing) to a plastic (the TPE/TPO core).

Burr and Felt Backings:

These materials excel in lamination. Because they are porous textiles, the molten TPE or TPO layer physically penetrates the fibers during the heating process. This creates a mechanical lock once the material cools.

- Process: Typically uses flame lamination or hot melt adhesive.

- Efficiency: The bond is instant. There is no need for curing time.

- Compatibility: Highly compatible with XPE foam interlayers. The heat fuses the foam surface, which then grips the fibrous burr backing immediately.

Maxpider Backing:

Bonding Maxpider requires precise temperature control. Since it is a proprietary mesh, the lamination heat must be high enough to melt the adhesive layer but low enough not to damage the stiff “hook” structures of the backing itself.

- Challenge: If the lamination roller is too hot, you crush the Maxpider hooks, destroying the anti-slip function.

- Solution: Manufacturers often use a lower-temperature hot-melt film specifically for this layer.

Rubber Spikes (Injection Molded):

There is usually no “bonding” here. The spikes are formed simultaneously with the mat. But here is the headache: if you are manufacturing a composite mat (e.g., leather top with rubber spike bottom), you face a massive hurdle. Adhesives struggle to bond with oily PVC formulations. You often have to stitch the layers together, which punctures the waterproof barrier.

Analogy: Think of bonding burr backing like chemical cross-linking where the materials fuse to become one unit. In contrast, attaching a heavy rubber spike layer to a leather top is like mechanical upholstering; it often requires stitching or rivets because the materials refuse to fuse chemically.

Equipment requirements for heavy spike molding versus textile fusing

The machinery on your factory floor dictates your capacity. The equipment needed for spikes is vastly heavier and more energy-intensive than for textile backings.

Injection Molding (Spikes):

To force thick rubber into a mold cavity to form 3mm-5mm spikes, you need high clamping pressure.

- Machine Size: Requires large tonnage injection molding machines (often 500T+ for full sets).

- Tooling: The molds must be machined from hardened steel to withstand the pressure. Creating thousands of tiny cavities for the spikes is expensive and time-consuming.

- Energy: You must heat a large volume of PVC to a flowable state.

Hot Press / Lamination (Burr & Maxpider):

This process is lighter and faster.

- Machine Size: Uses calendar rollers or vertical hot press machines.

- Tooling: Molds are simpler (often aluminum) because they only need to shape the 3D contour, not fill tiny spike holes.

- Energy: You are only heating the surface layers to fuse them, not melting the entire product mass.

| Equipment Factor | Injection Molding (Spikes) | Hot Press / Lamination (Textile) |

|---|---|---|

| Clamping Force | High (Heavy Duty) | Low to Medium |

| Mold Cost | High (Complex machining) | Lower (Simpler geometry) |

| Energy Usage | High (Melting bulk material) | Moderate (Surface fusing) |

Reducing raw material waste and production cycle time

Time is the most expensive resource in manufacturing. The backing type directly dictates how fast you can cycle your machines.

Cycle Time Analysis:

- Spikes: Rubber is an insulator; it holds heat. After injecting a thick rubber mat with spikes, you must wait for it to cool down enough to eject it without warping.

- Typical Cycle: Can range from 60 to 90 seconds per piece depending on thickness.

- Burr/Maxpider: These mats are mostly air (foam) and thin textile. They hold very little heat. Once pressed, they cool rapidly.

- Typical Cycle: Often 20 to 45 seconds in a hot press.

Waste Reduction:

Injection molding often produces “flash” (excess material that leaks between mold halves). This flash must be trimmed and recycled. If the recycled PVC contains impurities, it can clog the tiny spike cavities in the next run, causing defects.

Textile backings (Burr/Maxpider) come in rolls. While there is off-cut waste when cutting the shape, the lamination process itself is clean. There is no “flash” to trim from the backing layer. This eliminates a secondary trimming station on your production line.

Performance Metrics and Durability Standards

Maxpider and burr backings typically achieve superior lateral grip through mechanical interlocking, unlike rubber spikes that rely on heavy mass for friction. In durability testing, thermally fused textile backings resist delamination significantly better than glued assemblies under high cabin temperatures. Furthermore, the lightweight nature of fiber-based backings can reduce shipping weight by approximately 40% compared to traditional PVC mats.

Friction coefficient comparison on automotive carpet

Safety is the primary metric for any floor mat. If a mat slides under the brake pedal, it becomes a liability. The industry measures this using a “resistance to sliding” test.

The Mechanics of Grip:

- Rubber Spikes: These rely on vertical force. The mat must be heavy. The spikes need to sink into the carpet pile. However, on modern cars with tight, short-pile carpeting, spikes often float on top. They fail to “bite” effectively.

- Maxpider & Burr: These rely on lateral friction. The stiff fibers (Maxpider) or rough texture (Burr) grab the carpet loops sideways. They do not need weight to work.

Testing Standards:

In a standard pull test (where a force gauge pulls the mat horizontally), Maxpider types often show higher resistance than spikes on loop-pile carpets. The stiff bristles of Maxpider act like the teeth of a gear meshing with the carpet fibers. Spikes act more like a friction brake that can slip if the pressure (weight) isn’t high enough.

Industry Note: Friction coefficients vary based on the OEM carpet density (GSM). A backing that grips a Toyota carpet well might slip on a Jeep’s rubberized floor. Always perform specific pull-tests on your target vehicle’s flooring material.

Resistance to delamination under high heat and humidity

Automotive interiors are harsh environments. In summer, cabin temperatures can exceed 70°C (158°F). This heat destroys weak bonds.

The Failure Point:

Traditional composite mats often fail at the adhesive layer. If you glue a leather top to a rubber spike bottom, the glue softens in the heat. Humidity accelerates this breakdown. What happens next? “Delamination,” where the layers peel apart like an old shoe sole.

The Fusion Advantage:

Burr and Maxpider backings are rarely glued. They are laminated.

- Process: The manufacturing process uses flame or hot-press lamination.

- Result: The XPE foam core melts slightly and fuses directly into the fiber backing.

- Durability: This creates a physical bond, not a chemical one. The backing becomes part of the foam.

In environmental chamber testing (cycling between -40°C and +80°C), laminated textile backings show almost zero separation. Glued rubber assemblies often show edge peeling after just a few cycles.

Impact of backing weight on shipping and logistics costs

For a manufacturer, weight is not just a product feature; it is a cost driver.

The Weight Discrepancy:

- PVC Spikes: Rubber is dense. A full set of injection-molded PVC mats can weigh 6kg to 8kg.

- Textile Backing: A set of XPE mats with Maxpider or Burr backing typically weighs 1.5kg to 2.5kg.

Logistics Calculation:

This difference fundamentally changes your shipping strategy. Consider a 40-foot High Cube container.

- If shipping heavy PVC mats, you will likely hit the container’s weight limit before you fill the volume. You are shipping “dead air.”

- If shipping lightweight textile mats, you can fill the container’s volume completely without hitting the weight limit.

Cost Efficiency:

By switching to lightweight backings, you can often fit 30% to 50% more product sets into the same container. Why pay freight for dead weight? This drastically lowers the “freight cost per unit.”

| Feature | PVC Spikes | Maxpider / Burr |

|---|---|---|

| Grip Source | Weight + Gravity | Surface Friction |

| Heat Resistance | High (Material), Low (if Glued) | High (Fused Bond) |

| Typical Set Weight | 6.0kg – 8.0kg | 1.5kg – 2.5kg |

| Logistics | Weight-Limited | Volume-Limited |

Cost Analysis and Market Application Trends

While generic fiber burr backings offer the lowest entry cost due to abundant textile supply and reduced shipping weight, genuine Maxpider materials command a premium price due to patent royalties and limited sourcing channels. So, what’s the play? Manufacturers are increasingly shifting toward non-branded “soft burr” alternatives to meet the rising demand for lightweight, eco-friendly composite mats without incurring the high legal and licensing costs associated with proprietary technologies.

Raw material cost differences between PVC spikes and fiber burr

Cost is the deciding factor for most high-volume production runs. When you compare the bill of materials (BOM), the difference lies in how you buy the material.

PVC Spikes (Raw Resin):

You typically buy PVC in pellet or granule form. It is sold by weight (per ton).

- Usage Rate: Because injection molding requires a thick base to hold the spikes, you use a large volume of material per mat. Even if the price per kg is low, the cost per unit is high because you use so much of it.

- Efficiency: The process is material-heavy.

Fiber Burr (Roll Stock):

You buy this as a finished textile roll, sold by the square meter or yard.

- Efficiency: You pay for surface area, not mass. Since the backing is thin, one roll covers hundreds of mats.

- Cost vs Yield: The initial purchase cost of burr per square meter is often 20-30% lower than the equivalent amount of PVC needed to mold a spiked base.

The “Hidden” Cost of Waste:

With PVC, you can regrind and recycle waste, but it costs energy. With burr backing, you cannot recycle the off-cuts back into the same backing layer easily. But here is the kicker: this is usually offset by the speed of lamination.

Navigating patent restrictions while sourcing Maxpider alternatives

“Maxpider” is not just a material; it is effectively a brand and a patented technology associated with 3D Mats (U-Ace). This creates a legal minefield for manufacturers.

The Patent Barrier:

You cannot simply replicate the exact stiff-hook structure of Maxpider without risking a lawsuit. The specific geometry of the “kagu” style hook is protected intellectual property in many regions.

- Sourcing Risk: If you buy “Maxpider” backing from an unauthorized factory, your customized mats could be seized at customs.

The “White Label” Solution:

To avoid this, smart manufacturers source “Soft Burr” or “Anti-Skid Claw” backings.

- Legal Safety: These materials use a chaotic fiber structure—similar to a heavy-duty scouring pad texture—rather than a patented geometric hook. They achieve similar grip without infringing on the specific design patent.

- Market Acceptance: Most B2B clients do not care about the brand name “Maxpider.” They only care about the function. If you market it as “Premium Anti-Slip Fiber,” it meets the functional requirement perfectly.

| Feature | Genuine Maxpider | Generic Soft Burr / Anti-Skid |

|---|---|---|

| IP Status | Patented / Trademarked | Open Market / Generic |

| Sourcing | Restricted (Licensed) | Widely Available |

| Legal Risk | High (if unlicensed) | Low |

| Cost | Premium (Royalties) | Standard Commodity |

Market shift towards lightweight and eco-friendly composite mats

The automotive industry is undergoing a massive transformation, primarily driven by Electric Vehicles (EVs). This shift is forcing mat manufacturers to change their materials.

The EV Weight Factor:

EV manufacturers fight for every gram of weight to extend battery range. They do not want heavy rubber mats in the car.

- Trend: OEMs and aftermarket buyers now prefer lightweight composite mats (TPE + Foam + Burr).

- Obsolescence: Heavy PVC mats with rubber spikes are becoming “old tech.” They are seen as too heavy for modern, efficiency-focused vehicles.

The “Odorless” Premium:

Traditional rubber spikes (especially cheap PVC) off-gas and smell like chemicals in a hot car.

- Consumer Demand: Buyers now demand “odorless” interiors.

- Advantage: Textile backings (Burr/Maxpider) are chemically inert. They do not smell. This allows you to market your product as a “Healthy” or “Eco-friendly” upgrade.

Summary of Opportunity:

By moving away from PVC spikes, you align your product with the future of the auto industry. You are not just saving on shipping; you are creating a product that fits the “luxury” and “green” narrative that modern car owners are buying. This also significantly impacts your long-term profitability.

Conclusion

The shift from heavy rubber spikes to textile-based backings like Burr and Maxpider is not merely a design trend; it is a fundamental manufacturing evolution. For the factory owner, the transition to textile backings offers cleaner production cycles, reduced raw material volatility, and significantly lower logistics costs. While genuine Maxpider technology provides a premium, patented solution, generic soft burr backings offer a highly scalable and cost-effective alternative that meets modern OEM standards for safety and sustainability. As the market moves toward lightweight EVs, adapting your production line to handle hot-press lamination and textile bonding is essential for staying competitive in the global supply chain.