-

Whatsapp +86 13526654721

-

Email: sales@carmatrolls.com

-

Address: AUX Industrial Park, Shangjie District, Zhengzhou City, Henan Province, China

-

Whatsapp +86 13526654721

-

Email: sales@carmatrolls.com

-

Address: AUX Industrial Park, Shangjie District, Zhengzhou City, Henan Province, China

XPE Foam in Car Mats: Insulation and Comfort Explained

What makes XPE foam the superior choice for automotive floor mats compared to traditional materials?

XPE (Chemical Cross-linked Polyethylene) foam serves as a premium intermediate layer in car mats, offering superior acoustic and thermal insulation due to its closed-cell structure. It provides long-term ergonomic comfort, resists water and chemical degradation, and eliminates the toxic off-gassing associated with traditional materials like EVA, making it a safer and more durable solution for automotive interiors.

Acoustic and Thermal Insulation Performance

How does the internal structure of XPE foam actually prevent noise and heat from entering a vehicle’s cabin?

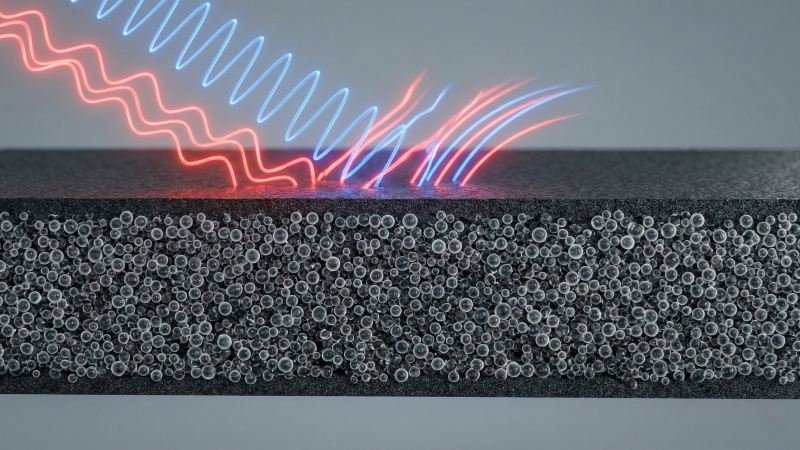

Chemical Cross-linked Polyethylene (XPE) foam utilizes a distinct closed-cell structure where millions of tiny, independent air bubbles are permanently trapped within a polymer matrix. This physical barrier effectively disrupts sound wave transmission to reduce road noise and minimizes thermal conductivity, preventing chassis heat from penetrating the interior.

The role of closed-cell structure in noise dampening

The primary reason XPE foam is effective at reducing cabin noise lies in its cellular geometry. Unlike open-cell materials (similar to standard acoustic absorbing foam) where air and sound flow freely through interconnected tunnels, XPE features sealed, individual pockets of gas.

When sound waves from the road or the engine strike the car mat, they cannot simply pass through the material. Instead, the energy is forced to travel through the complex matrix of polymer walls. This process dissipates the acoustic energy, significantly lowering the volume that reaches the driver’s ears. In the automotive manufacturing industry, this is crucial for improving NVH (Noise, Vibration, and Harshness) levels.

Consider the difference between a standard OEM floor carpet and a dedicated sound-deadening sheet applied to a door panel. A standard carpet allows sound to pass through, merely muffling the echo. In contrast, XPE acts similarly to the sound-deadening sheet; it functions as a barrier that blocks the transmission of low-frequency rumble generated by tires rolling on asphalt.

Key Acoustic Benefits:

- Vibration Damping: The foam absorbs the micro-vibrations from the vehicle’s chassis before they become audible noise.

- Transmission Loss: It creates a “dead zone” that stops sound waves from traveling from the floor pan to the cabin air.

- Frequency Filtering: XPE is particularly effective at filtering out high-frequency road hiss.

Note: The effectiveness of sound dampening is directly related to the foam’s density. Higher density XPE generally offers superior sound blocking capabilities. Since density specifications (often measured in kg/m³) vary between manufacturers, always confirm the specific density rating with your supplier to ensure it meets your acoustic requirements.

Heat rejection properties for climate control efficiency

Beyond sound, the vehicle floor is a major entry point for external heat. The exhaust system—often running directly beneath the center console—and friction from the road surface generate significant thermal energy. XPE foam serves as a thermal insulator due to its low thermal conductivity.

Thermal conductivity refers to how easily a material allows heat to move through it. Because air is a poor conductor of heat, the millions of trapped air bubbles within XPE foam act as a shield. This prevents the intense heat radiating from the vehicle’s undercarriage from warming up the interior floor.

This insulation works both ways. In the summer, it stops chassis heat from entering. In the winter, it prevents the warm air inside the cabin from escaping through the cold metal floor. Consequently, the vehicle’s air conditioning and heating systems do not have to work as hard to maintain the desired temperature.

Comparison of Thermal Conductivity:

| Material Type | Thermal Insulation Capability | Primary Function |

|---|---|---|

| Standard OEM Needle Felt | Low | Surface protection and aesthetics |

| XPE Foam | High | Thermal barrier and heat rejection |

| Solid Rubber | Medium | Durability and waterproofing |

By acting as a thermal break, XPE ensures that the surface your feet rest on remains temperature-neutral, regardless of how hot the catalytic converter or exhaust pipes underneath the chassis become.

Ergonomics and Physical Comfort Factors

Does the material of a car mat actually affect driver fatigue and physical comfort during long commutes?

XPE foam improves driver ergonomics by offering a semi-rigid cushion that absorbs chassis vibration and reduces stress on the heel and ankle joints. Its cross-linked structure prevents the foot from sinking into the mat, providing a stable platform for pedal operation while maintaining enough elasticity to dampen the physical impact of road irregularities.

Shock absorption capabilities for long-distance driving

Driving a vehicle involves constant physical contact between the driver’s feet and the floor. When a car travels over asphalt, the tires generate kinetic energy. This energy travels through the suspension and vibrates the metal floor pan. Without adequate dampening, these high-frequency vibrations transfer directly into the driver’s heel.

XPE foam functions similarly to a suspension bushing in a vehicle’s undercarriage. Just as a rubber bushing isolates a control arm from the vehicle frame to stop vibration transfer, the XPE layer isolates the driver’s foot from the vibrating chassis. It acts as a buffer zone.

This is critical for the “throttle foot.” During long-distance driving, the driver’s heel rests in a fixed position for hours. A hard surface, like bare plastic or thin rubber, transmits every bump. XPE foam absorbs these micro-shocks before they reach the skeletal structure of the foot.

Impact on Driver Fatigue:

- Vibration dampening: Reduces the “buzzing” sensation in feet that causes numbness.

- Impact cushioning: Softens the blow when stepping firmly on the brake in emergencies.

- Joint support: Reduces strain on the ankle joint by absorbing minor road jolts.

Compression resistance and long-term shape retention

A major issue with automotive interiors is material degradation under load. This is often seen in driver seats that sag over time. Floor mats face a similar challenge. The driver’s heel applies concentrated pressure to a very small area of the mat, specifically directly under the accelerator and brake pedals.

XPE (Cross-linked Polyethylene) is engineered to resist this permanent deformation. This property is known in the industry as Compression Set Resistance.

The chemical cross-linking process creates a strong, three-dimensional network between the polyethylene molecules. Think of it like a high-quality automotive weatherstrip seal on a car door. When you open the door, the seal compresses, but when you open it again, it immediately springs back to its original shape. It does not stay flattened. XPE foam behaves the same way under your feet.

Inferior linear foams lack this structural memory. Once compressed, the air bubbles burst or the walls collapse, leaving a permanent dent. XPE walls are strong enough to bend under weight and rebound once the pressure is removed.

Visualizing Compression Performance:

| Feature | Standard Linear Foam | XPE Foam (Cross-linked) |

|---|---|---|

| Molecular Structure | Unconnected chains | 3D Web / Net structure |

| Response to Load | Collapses / Flattens | Deflects and Rebounds |

| Long-term Result | Permanent heel indentation | Maintains flat surface |

This retention of thickness is vital for safety. If a mat compresses too much, it can change the distance between the heel and the pedal. XPE maintains a consistent thickness throughout the vehicle’s lifespan, ensuring the driving position remains constant.

Safety, Hygiene, and Chemical Stability

Is XPE foam safe for passenger health and easy to maintain in a hygienic condition?

XPE foam is chemically stable, non-toxic, and odorless because it is manufactured using thermal cross-linking rather than chemical adhesives that release volatile organic compounds (VOCs). Additionally, its closed-cell structure creates an impermeable barrier against liquids, effectively preventing moisture accumulation, mold formation, and bacterial growth within the vehicle cabin.

Absence of volatile organic compounds and odors

A common complaint with new car accessories is the strong, chemical smell they release. This is often referred to as “off-gassing.” This typically happens when materials contain unstable chemicals or cheap glues. When these materials get hot, they release gas into the air.

XPE foam is different because of its manufacturing process. It is produced without the heavy metal stabilizers often found in PVC. Instead, XPE uses a thermal bonding process. This means the layers are fused together using heat, not toxic liquid adhesives.

In the automotive industry, we measure this safety using a Fogging Test. This test checks if a material releases gases that condense on the windshield, creating a greasy film. High-quality XPE foam has very low fogging values. It behaves like the hard plastic used in your car’s dashboard: it is solid, stable, and does not evaporate.

Why XPE is Safer in Summer:

- Heat Stability: Inside a parked car, temperatures can reach extremely high levels. XPE remains stable and does not break down or release toxic fumes even at high temperatures.

- Odorless: It does not produce the “burnt rubber” smell associated with lower-quality rubber mats.

- Non-Toxic: It is generally free from substances like formaldehyde and heavy metals.

Note: While XPE is generally heat resistant up to approximately 80°C – 100°C, the maximum safe operating temperature can vary depending on the specific polyethylene blend.

Waterproof characteristics preventing mold and bacterial growth

Hygiene is just as important as chemical safety. The floor of a car is a trap for dirt, rain, and spilled drinks. If a material absorbs these liquids, it becomes a breeding ground for bacteria and mold.

XPE foam is inherently hydrophobic. This means it repels water. This property comes from its closed-cell structure. Think of the rubber window seals on your vehicle. Rainwater hits them and runs off; it does not soak in. XPE works exactly the same way.

When you spill milk or coffee on an XPE mat, the liquid sits on the surface as droplets. It cannot penetrate into the foam. This prevents the liquid from reaching the carpet underneath the mat.

Comparison of Hygiene Risks:

| Material Structure | Reaction to Spilled Liquid | Hygiene Consequence |

|---|---|---|

| Open-Cell (e.g., Carpet/Sponge) | Absorbs liquid deeply | Bacteria grow inside; bad smells develop |

| Closed-Cell (XPE Foam) | Liquid pools on surface | Easy to wipe; no internal mold growth |

| Fibrous Mat (e.g., Coconut fiber) | Traps moisture in fibers | Rot and mildew formation over time |

Because the moisture never enters the material, XPE mats do not develop the sour, musty odor often found in older vehicles. You can simply wipe them clean with a wet cloth, restoring the sanitary condition of the cabin immediately.

Comparing XPE Against Common Alternatives

How does XPE foam actually stack up against popular alternatives like EVA and TPE when it comes to longevity and grip?

XPE foam demonstrates superior durability compared to EVA by maintaining structural integrity without powdering or deformation over time due to its cross-linked nature. When compared to TPE, XPE offers better thermal and acoustic insulation but generally requires a textured surface treatment to match the inherent anti-slip properties of rubber-like thermoplastic elastomers.

Differences in durability between XPE and EVA foam

In the car mat industry, EVA (Ethylene Vinyl Acetate) was the standard for many years. However, XPE (Cross-linked Polyethylene) has largely replaced it in premium segments due to distinct physical differences. The primary distinction lies in how the materials age inside a vehicle.

EVA foam is chemically similar to the material used in generic foam shoe soles. Over time, heat and oxidation attack the molecular bonds of EVA. This causes the material to dry out and become brittle. In the automotive interior industry, this failure mode is known as “powdering” or “chalking.”

Imagine the weather stripping on an old car door that crumbles into black dust when you touch it. EVA mats behave similarly after a few years of exposure to sunlight and changing temperatures. They lose their elasticity and start to flake off.

In contrast, the cross-linking process of XPE creates a permanent bond between the polymer chains. This makes the foam significantly more resistant to environmental stress. It does not crumble or turn to dust.

Comparative Durability Analysis:

| Feature | EVA Foam (Common Grade) | XPE Foam (Automotive Grade) |

|---|---|---|

| Aging Reaction | Becomes brittle and cracks | Remains flexible |

| Heat Resistance | Shrinks or warps above 50°C | Stable up to ~80°C |

| Physical Form | Prone to “powdering” (disintegration) | Maintains solid surface |

| Typical Lifespan | 1 – 2 Years | 3 – 5+ Years |

Trade-offs between XPE insulation and TPE anti-slip features

TPE (Thermoplastic Elastomer) is another major competitor in the car mat market. TPE mats are typically injection-molded, looking like a solid piece of rubber. When choosing between XPE and TPE, you are essentially choosing between insulation and friction.

TPE is a dense material. It is excellent at gripping the floor and the driver’s shoe because it has a naturally high coefficient of friction. It acts like a rubber tire; it does not slide easily. However, because TPE mats are usually single-layer and dense, they are poor insulators. They transfer sound and heat almost as easily as the bare metal floor.

XPE, as discussed, is filled with air bubbles. This makes it a superior insulator against noise and heat. However, raw XPE foam can be slippery. Therefore, XPE is rarely used as a single layer. It acts as the core material in multi-layer mats (often called 5D or 7D mats), usually covered with artificial leather to provide grip.

Think of the difference like this:

- TPE Mat: Like a hard rubber boot tray. It is waterproof and rugged, but offers no cushioning or warmth.

- XPE Mat: Like a padded carpet underlay. It provides softness and quietness, but needs a top cover to handle wear and tear.

Material Characteristic Trade-offs:

| Performance Metric | TPE (Injection Molded) | XPE (Multi-layer Core) |

|---|---|---|

| Acoustic Insulation | Low (Transmits noise) | High (Absorbs noise) |

| Thermal Insulation | Low (Transfers heat) | High (Blocks heat) |

| Surface Grip | Excellent (Naturally anti-slip) | Moderate (Requires texture) |

| Tactile Feel | Hard / Rubbery | Soft / Cushioned |

Consequently, manufacturers often combine these materials. They might use an XPE core for the main floor coverage to ensure quietness, while placing a TPE heel pad under the pedals to ensure non-slip safety.

Identifying Genuine XPE Materials During Purchase

How can a buyer distinguish between high-quality XPE foam and cheaper substitutes without using laboratory equipment?

Genuine XPE foam is identified by its fine, uniform cellular structure visible in the cross-section and a firm, semi-rigid tactile response that rebounds immediately after compression. Unlike lower-grade alternatives which often emit strong chemical odors and feel spongy, authentic XPE is odorless and burns with a clear flame and a paraffin-like scent when tested.

Visual and tactile signs of high-density polyethylene foam

The most immediate way to verify the material is through physical inspection. You do not need to be a scientist; you just need to look closely at the edge of the mat.

First, examine the Cross-Section. If the mat is not fully wrapped in leather, find an exposed edge. Genuine XPE foam possesses a very fine, consistent structure. The bubbles are microscopic and uniform. It looks similar to the high-density protective foam used in electronics packaging.

In contrast, cheaper foams like EPE (Pearl Cotton) or low-grade EVA often show large, uneven bubbles. Their structure resembles a coarse bath sponge or packing peanuts.

Next, perform the Thumb Press Test. Press your thumb firmly into the center of the mat.

- Genuine XPE: It will feel firm but yielding. When you release your thumb, the foam snaps back to its original shape almost instantly. It has a “memory.”

- Inferior Material: If it feels overly soft and takes several seconds to recover, it is likely standard sponge or low-density EVA. If it feels rock-hard like hard plastic, it is likely TPE or PVC.

Tactile Checklist:

- Smoothness: The raw surface of XPE is smooth and silky, not rough or gritty.

- Rigidity: It should hold its shape when held in the air, rather than flopping over like a wet towel.

- Density: It should feel lightweight but solid, not airy or hollow.

Pro Tip: Since foam density can vary by manufacturer grade, it is helpful to ask for a small sample swatch to compare the firmness directly before placing a bulk order.

The flame and smell test for material verification

If visual inspection is inconclusive, the combustion test is the most definitive method used in the plastics industry to identify polymer types. This is a destructive test, so it should only be performed on a small sample piece or a hidden corner.

Polyethylene (PE), the base material of XPE, has a distinct burning signature. When you light a small strip of XPE foam:

- The Flame: It burns with a yellow tip and a blue base. It does not self-extinguish immediately.

- The Smoke: It produces very little smoke. The smoke is usually white or light gray.

- The Smell: This is the most obvious indicator. Burning XPE smells like burning candle wax (paraffin). It is not offensive.

Compare this to EVA or PVC substitutes. When these materials burn, they often release thick, black sooty smoke. More importantly, they produce a sharp, acrid odor. PVC specifically smells like chlorine or vinegar, which stings the nose.

Combustion Characteristics Table:

| Material | Flame Appearance | Smoke Color | Smell | Residue |

|---|---|---|---|---|

| Genuine XPE | Yellow tip, Blue base | White / Light Gray | Candle Wax (Paraffin) | Molten droplets |

| EVA Foam | Yellow, lively flame | Darker Gray | Sour / Vinegar-like | Sticky tar |

| PVC | Sputtering flame | Thick Black | Acrid / Chlorine | Hard black char |

Note: Some automotive XPE mats are treated with fire-retardant additives for safety compliance. If the material is certified as “fire-retardant,” verify the specific flammability standards (such as FMVSS 302) with the supplier, as this may affect the results of a standard burn test.

Conclusion

Choosing the right car mat is about more than just aesthetics; it is about creating a driving environment that is quiet, comfortable, and safe. XPE foam represents a significant technological leap in automotive interiors. By combining the noise-dampening properties of a closed-cell structure with the physical resilience of cross-linked polyethylene, XPE offers a balanced solution that traditional materials like EVA cannot match. Whether you prioritize reducing cabin noise, ensuring a chemical-free interior for your family, or simply want a durable mat that won’t lose its shape, understanding the specific properties of XPE ensures you can make an informed investment in your vehicle’s comfort.