-

Whatsapp +86 13526654721

-

Email: sales@carmatrolls.com

-

Address: AUX Industrial Park, Shangjie District, Zhengzhou City, Henan Province, China

-

Whatsapp +86 13526654721

-

Email: sales@carmatrolls.com

-

Address: AUX Industrial Park, Shangjie District, Zhengzhou City, Henan Province, China

Custom Logo Plates for Car Mats: Metal and PVC Branding Options

How do you choose between the premium look of metal and the practical durability of PVC when branding automotive floor mats?

The choice between Metal and PVC logo plates depends on the specific balance between luxury aesthetics and functional safety: Zinc Alloy and Aluminum offer a high-value, rigid finish ideal for carpeted interiors, whereas Soft PVC provides necessary flexibility, impact resistance, and anti-slip properties for heavy-duty all-weather mats. Ultimately, the decision must factor in the target market’s preference for visual prestige versus rugged utility.

Analyzing Material Performance in Automotive Conditions

How do different branding materials withstand the unique physical stresses and environmental factors found inside a vehicle cabin?

The optimal material choice depends on the specific branding objective: Zinc Alloy and Aluminum offer a high-gloss, rigid finish ideal for luxury automotive aesthetics, whereas Soft PVC and Rubber provide superior friction resistance, flexibility, and safety for heavy-duty all-weather mats. Selection requires balancing visual impact against the practical need for traction and corrosion resistance.

Zinc Alloy and Aluminum for Premium Aesthetics

When the primary goal is to elevate the perceived value of a floor mat, metal serves as the industry standard. This mirrors the design philosophy of luxury automotive interiors, where brushed metal trim is used on dashboards and door panels to signal quality through rigidity and a “cold touch” feel. Zinc alloy allows for precise die-casting. This process creates sharp, high-relief 3D logos that stand out visually against the soft texture of the carpet.

Aluminum offers a slightly different aesthetic. It is typically stamped rather than cast. This gets you a thinner profile that works well for brushed or anodized finishes. The reflective surface of these metals catches the light from under-dash footwell lighting, drawing attention to the brand. This visual pop is difficult to achieve with matte plastic materials.

But there is a catch. The rigid nature of metal introduces a performance trade-off. Metal plates do not flex. If the floor mat bends—for example, during removal for cleaning or installation—a long, thin metal plate might warp or detach. Therefore, rigid metal plates perform best on high-pile carpet mats that have a stiff backing layer, similar to how a rigid emblem is securely mounted to a car’s front grille rather than a flexible bumper component.

Soft PVC and Rubber for Safety and Grip

While metal looks premium, Soft PVC (Polyvinyl Chloride) and rubber prioritize function and safety. In the automotive interior, the floor area experiences the most friction. A driver’s heel constantly pivots between the gas and brake pedals, creating a high-wear heel zone. A smooth metal plate in this specific area can be dangerous as it becomes slippery when wet. Would you want a slippery metal plate under your heel during a panic stop?

Soft PVC offers a higher coefficient of friction. This means it creates more “grip” against the shoe sole, preventing the driver’s foot from sliding during sudden braking. Beyond grip, PVC brings a mechanical advantage: flexibility. It bends with the mat, making it the superior choice for TPE (Thermoplastic Elastomer) or rubber all-weather mats that are frequently rolled up or shaken out.

We measure the hardness of these materials using the Shore A durometer scale. A standard car mat logo usually ranges between 50A and 60A hardness. This is firm enough to hold detail but soft enough to prevent injury. If a driver enters the car barefoot or wearing open sandals, a soft rubber badge will not scratch the skin or damage the heel of a leather shoe, unlike the potentially sharp edge of a metal badge.

Corrosion Resistance Against Water and Road Salt

Floor mats face harsher conditions than any other interior component. They trap water, mud, and, in colder climates, road salt. Road salt is highly corrosive and accelerates rust.

Metal Performance:

Untreated steel will rust quickly, turning orange. That’s why we stick to Zinc Alloy or Aluminum. But raw metal isn’t enough. Zinc alloy requires electroplating (usually chrome or nickel) to seal the surface. If this plating is thin or scratched, the salt will penetrate and cause “pitting,” which looks like small black dots. Aluminum naturally resists red rust, but it can suffer from oxidation. This appears as a chalky white powder on the surface.

PVC Performance:

PVC is chemically inert regarding rust. It reacts differently to the environment. It does not corrode from water or salt. Its main weakness is UV exposure over long periods, which can cause colors to fade. However, modern automotive-grade PVC usually includes UV stabilizers to prevent this.

Note: The thickness of electroplating on metal badges varies significantly by supplier. It is crucial to confirm the specific salt spray test rating (typically measured in hours, e.g., 24h or 48h) to ensure it meets the durability requirements for your target market’s climate.

Comparison of Material Durability in Wet Conditions

| Feature | Zinc Alloy (Plated) | Aluminum (Anodized) | Soft PVC / Rubber |

|---|---|---|---|

| Water Resistance | High (if plating is intact) | High | Excellent |

| Salt Corrosion Risk | Moderate (Pitting risk) | Low (Oxidation risk) | None |

| Scratch Resistance | High | Moderate | Low (Can scuff) |

| Maintenance | Needs polishing | Wipe clean | Wash with soap |

Attachment Mechanisms for Secure Fitment

What is the most effective method to ensure a custom logo plate remains permanently attached to a car floor mat despite constant foot traffic and vibration?

The attachment mechanism relies entirely on the underlying mat material: “Bendable Legs” with backing plates are the industry standard for penetrating woven carpet mats, while “Screw and Washer” systems provide necessary clamping force for dense rubber or TPE all-weather mats. For maximum durability and safety, these mechanical fasteners should be paired with a recessed mounting area to ensure the badge sits flush with the mat surface.

Bendable Legs for Penetrating Carpet Mats

Carpet mats, unlike rubber ones, consist of fibers woven into a backing. To attach a metal or hard plastic plate here, manufacturers use a method similar to attaching automotive trim clips. The logo plate features two or more metal “legs” or prongs on its rear side.

These legs are typically made from the same zinc alloy or aluminum as the face. During installation, the legs pierce through the carpet pile and the stiff backing layer. Once they poke through the other side, an installer places a flat metal washer over the legs. From there, it’s just a matter of bending the legs outward or inward to lock the plate in place.

Why Use Washers?

You cannot simply bend the legs against the carpet backing directly. The backing, usually made of latex or coarse mesh, is too soft. Without a washer, the metal legs would eventually tear through the fabric as the mat flexes. The washer acts like a load spreader. It distributes the pressure over a wider area, just like a washer prevents a bolt from pulling through a plastic fender liner.

Note: The length of these attachment legs usually ranges from 10mm to 15mm. However, carpet thickness varies greatly between “economy” needle-punch mats and “luxury” tufted mats. Always verify the leg length fits your specific carpet backing thickness.

Screw and Washer Systems for Heavy Duty Rubber Mats

Rubber and TPE (Thermoplastic Elastomer) mats present a different challenge. They are dense, solid, and often impermeable. Trying to push a bendable leg through a thick rubber mat is difficult and may cause the mat to tear. You also have to fight the material itself—rubber has “elastic memory,” meaning it tries to push objects back out.

For these heavy-duty applications, a screw system is superior. This setup functions similarly to a threaded rivet used in bodywork:

- The Female Part: The logo plate has threaded posts (bosses) on the back.

- The Connection: Two holes are punched cleanly through the rubber mat.

- The Male Part: Screws with wide, flat heads are inserted from the bottom of the mat up into the plate.

This method creates a clamping force. The screw pulls the plate down while pushing the washer up, sandwiching the rubber mat tightly in between. This mechanical lock is vital because adhesives rarely stick well to the oily surface of rubber or silicone-based TPE materials.

| Feature | Bendable Legs | Screw System |

|---|---|---|

| Best Substrate | Tufted Carpet / Nylon | Solid Rubber / PVC / TPE |

| Installation Speed | Fast (Manual or Machine) | Slower (Requires tools) |

| Clamping Style | Pinching | Sandwiching |

| Risk Factor | Legs snapping if bent twice | Screws loosening over time |

Recessed Mounting Strategies to Prevent Heel Snagging

Regardless of whether you use legs or screws, the physical profile of the badge matters. If a badge sits directly on top of a flat mat, it creates a “lip” or raised edge. In the automotive industry, we call this a “trip hazard.”

When a driver moves their foot from the accelerator to the brake, their heel slides across the floor. If the heel catches the edge of a raised metal plate, two things happen. First, it creates a safety risk by interrupting the braking motion. Second, the shear force eventually rips the badge off the mat.

The engineering fix? Design a “recess” or “debossed pocket” into the mat mold itself. This is a sunken area in the shape of the logo.

- Flush Fitment: If the logo plate is 3mm thick, the recess should be approximately 2.5mm to 3mm deep. This allows the top of the plate to sit flush (level) with the surrounding rubber ribs or carpet pile.

- Edge Protection: By sinking the plate into a pocket, the edges are protected by the surrounding mat material. The driver’s shoe slides over the top without ever hitting the side of the plate.

This is similar to how a modern car’s infotainment screen is often flush-mounted into the dashboard rather than bolted on top; it looks integrated and prevents snagging.

Design Constraints and Branding Execution

Why do precise digital logos often require modification before they can be successfully manufactured into physical car mat badges?

The feasibility of a branding execution is strictly dictated by the manufacturing limitations of the chosen material; metal die casting requires specific minimum line thicknesses to ensure molten metal flows correctly, whereas soft PVC utilizes physical ridges to separate liquid colors, necessitating different design file adaptations for each method.

Minimum Line Thickness for Metal Die Casting

When designing a metal plate, you cannot simply shrink a digital image. The physical mold, which is made of steel, has limits. During the die-casting process, we inject molten Zinc Alloy into the mold at high pressure. The liquid metal must flow into every tiny crevice before it cools and hardens.

If a line in your logo is too thin, the liquid metal cannot squeeze into that part of the mold. It creates a defect known in the molding industry as a “short shot.” This means the logo comes out incomplete or with missing letters. To prevent this, every line and gap must meet a minimum width requirement.

For most standard Zinc Alloy molds, the minimum line width is typically around 0.3mm to 0.5mm. Similarly, the text height usually needs to be at least 1.0mm to be legible. Think of this like CNC machining a mold; you cannot cut a groove narrower than the drill bit you are using. If the design is too intricate, you must simplify it or make the badge larger.

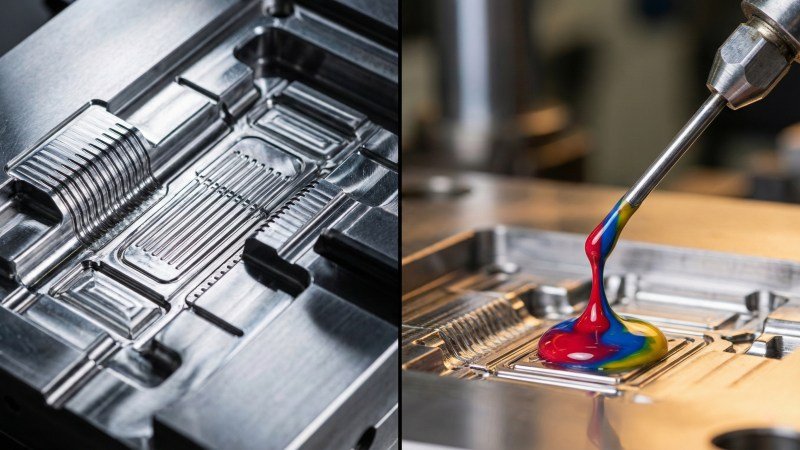

Multi-Color Layering and 3D Effects in Soft PVC

Soft PVC branding offers a unique advantage for colorful logos. Unlike metal, where colors are usually painted into recesses, PVC logos are built from different colored liquids. The manufacturing process involves dispensing liquid PVC into a heated mold.

However, liquids mix if they touch. To keep a red letter separate from a blue background, the mold must have a tiny wall between them. In the industry, we call these “separating ridges.” The trade-off? Your design cannot have gradient colors (fading from light to dark). Every color must be a solid block, separated by a thin line of material.

2D vs. 3D Execution:

- 2D Flat: The logo has sharp, square edges and a flat top surface. It looks crisp and clean.

- 3D Sculpted: The mold is carved with curved depths. This gives the logo a rounded, puffy appearance, similar to a domed resin sticker but much more durable.

This layering method means the color goes all the way through the material. It is not just a surface print that can scratch off.

Electroplating and Brushed Textures for Metal Plates

Metal plates rely on surface finishing to achieve their premium look. Since raw Zinc Alloy looks dull and gray, we use electroplating to add a layer of chrome, nickel, or gold. This chemical bath bonds a thin metal skin to the badge, protecting it and making it shine.

However, a mirror-like chrome finish shows every fingerprint. To solve this, many automotive brands prefer a Brushed Finish. In this process, the metal is physically scratched by an abrasive belt in a uniform direction. This creates a sophisticated, matte texture that hides scratches and reduces glare.

Combining Texture and Color:

Designers often combine these finishes with “Soft Enamel” filling. We recess the text area and fill it with colored epoxy paint, while leaving the raised metal borders polished or brushed.

| Feature | Electroplating | Brushed Finish | Soft Enamel Fill |

|---|---|---|---|

| Visual Effect | Mirror-like reflection | Matte, linear texture | Solid block color |

| Primary Use | Luxury/Classic look | Modern/Industrial look | Brand color matching |

| Durability | High hardness | Hides minor scratches | Resistant to fading |

Production Cost and Manufacturing Considerations

When planning a budget for automotive accessories, how do the upfront tooling investments and per-unit costs compare between metal die-casting and PVC molding?

The financial structure of these two methods is inversely related: Metal branding requires a high initial investment for steel molds, often ranging from $300 to $800, but offers lower unit costs at high volumes due to rapid automated casting. In contrast, PVC branding has a low entry barrier with mold costs between $50 and $150, yet the per-unit price remains higher because the production process involves labor-intensive manual dispensing and slower curing times.

Tooling Costs for Metal Molds versus PVC Molds

The “mold” or “tool” is the custom-made equipment required to shape your logo. The price difference here is substantial because the materials and processes used to make these tools are completely different.

Metal Die-Cast Molds:

To create a Zinc Alloy badge, we must inject molten metal at high pressure. Therefore, the mold must be made of hardened steel to withstand this force without warping. Cutting a logo into a block of hardened steel requires expensive CNC machines and Electrical Discharge Machining (EDM).

- Typical Cost: $300 to $1,000 (depending on size and complexity).

- Lifespan: These molds are durable and can produce hundreds of thousands of shots before wearing out.

Soft PVC Molds:

PVC molds do not need to withstand high pressure. The liquid PVC is simply dripped into the cavity. Because of this low pressure, we can cut these molds from softer metals like aluminum, copper, or magnesium. These materials are softer and faster to machine than steel.

- Typical Cost: $50 to $200.

- Lifespan: These molds wear out faster but are cheap to replace.

Impact of Order Quantity on Unit Price

In manufacturing, we look at the “amortization” of costs. This means spreading the initial mold cost over the total number of units purchased.

The “High MOQ” Dynamic of Metal:

Metal badges have a steep economy of scale. Once the expensive steel mold is made and the die-casting machine is set up, the machine can pump out parts very quickly (often one “shot” every few seconds).

- Small Orders (100-500 units): Extremely expensive. You are paying a high setup fee for a short run.

- Large Orders (10,000+ units): Very cheap. The unit price drops significantly because the labor cost per part is low.

The “Low MOQ” Dynamic of PVC:

PVC production is less automated. An operator often uses a dispenser to fill the colors into the mold by hand, or a machine does it slowly. Then, the mold must go through a baking oven to cure the plastic.

- Small Orders: Very affordable. Since setup is easy, suppliers often accept orders as low as 50 or 100 units.

- Large Orders: The price does not drop as dramatically as metal. The labor time required to fill and bake each mold remains constant regardless of volume.

Cost Comparison Scenario (Estimates)

| Order Quantity | Zinc Alloy (Metal) | Soft PVC (Rubber) | Verdict |

|---|---|---|---|

| 100 Units | High Unit Cost + High Mold Fee | Low Unit Cost + Low Mold Fee | PVC Wins |

| 1,000 Units | Moderate Unit Cost | Moderate Unit Cost | Tie / Preference |

| 50,000 Units | Lowest Unit Cost | Higher Unit Cost (Labor heavy) | Metal Wins |

Lead Times for Sample Development and Mass Production

Time is money, especially when launching a new car mat line for a specific season. The production timelines for these materials differ due to post-processing requirements.

Sample Development (Prototyping):

- PVC: Fast. A factory can cut an aluminum mold and bake a sample in 3 to 5 days. It is ideal for “rush” projects.

- Metal: Slow. Cutting steel takes longer. More importantly, after the metal part is cast, it must be polished and then sent to a separate electroplating facility. This plating step adds significant time. Expect 12 to 20 days for a metal sample.

Mass Production Speed:

Here is the irony: while metal takes longer to set up, it is faster to produce in bulk.

- Metal Injection: A machine can cycle automatically, producing parts instantly. This is comparable to an automated injection molding line for car bumpers—high speed once the line is running.

- PVC Curing: Each batch of PVC badges must sit in a hot oven to solidify. This heating and cooling cycle is a bottleneck, similar to how manual leather stitching requires more time per unit than automated cutting.

Important: Metal plating factories often face strict environmental inspections. If the government orders a temporary shutdown for environmental compliance, lead times for plated metal badges can double unexpectedly. Can your production schedule handle that uncertainty? PVC production is cleaner and rarely faces these specific delays.

Conclusion

The bottom line is simple: choosing between metal and PVC branding is not just a design choice; it is a functional decision. If your target market values showroom aesthetics and luxury, Zinc Alloy or Aluminum is the clear winner. However, if your product is designed for heavy-duty use, mud, and snow, Soft PVC offers the safety and durability your customers need. By understanding these material properties, attachment methods, and cost structures, you can select the branding solution that best elevates your automotive product line.