-

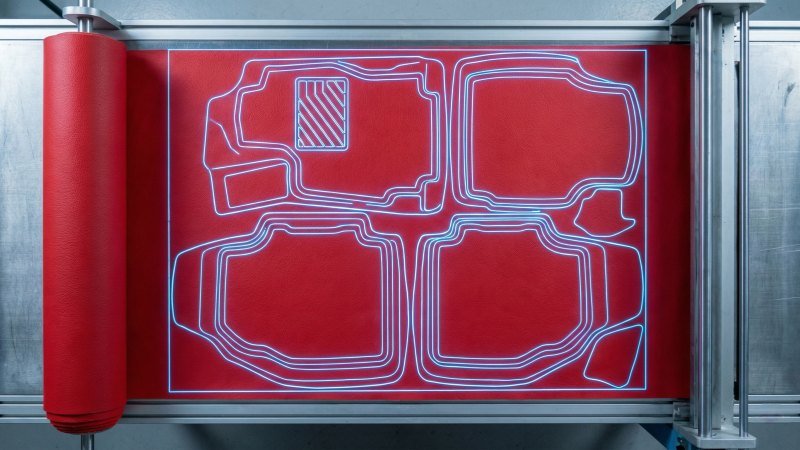

Whatsapp +86 13526654721

-

Email: sales@carmatrolls.com

-

Address: AUX Industrial Park, Shangjie District, Zhengzhou City, Henan Province, China

-

Whatsapp +86 13526654721

-

Email: sales@carmatrolls.com

-

Address: AUX Industrial Park, Shangjie District, Zhengzhou City, Henan Province, China

Top 5 Features to Look for When Buying a Car Mat Cutter

What are the critical specifications and technologies you must evaluate before investing in a digital car mat cutting machine?

The top five features to look for when buying a car mat cutter include high-frequency oscillating knife technology for smokeless processing, intelligent nesting software to maximize material yield, a partitioned vacuum adsorption platform for secure hold-down, an integrated vehicle model database for rapid pattern access, and an automatic feeding system to streamline high-volume roll production.

Feature 1: High-Frequency Oscillating Knife Technology

Why is high-frequency oscillating knife technology superior to laser cutting for car mat production?

Oscillating knife technology utilizes a physical blade that vibrates at high speeds to slice through materials, commonly referred to as “cold cutting.” This method creates clean, precise edges without producing heat, thereby eliminating the toxic smoke, burnt edges, and unpleasant odors associated with laser cutting.

Eliminating smoke and burnt edges compared to laser

When you select a cutter for car mats, the cutting method matters most. In the past, many manufacturers used CO2 laser machines. However, lasers use high heat to melt through the material. This process causes significant problems for car interior products.

Car mats are often made of PVC, rubber, or XPE materials. When a laser burns these materials, it creates a chemical reaction. This reaction produces black smoke and a strong, burnt smell. The smell can linger in the final product. Your customers will notice this odor immediately when they place the mats inside a closed vehicle.

Here is the better way: The oscillating knife uses mechanical vibration. It cuts like a high-speed saw but with a very fine blade. There is no heat involved. The material stays chemically stable. The edges remain the original color of the material rather than turning black or yellow from burning.

Comparison of Cutting Technologies for Car Mats

| Feature | Oscillating Knife (Cold Cut) | Laser Cutter (Thermal Cut) |

|---|---|---|

| Edge Quality | Smooth, original color | Burnt, black or yellowed edges |

| Odor | Odorless | Strong burnt smell (hard to remove) |

| Safety | No toxic fumes | Produces toxic smoke (requires exhaust) |

| Maintenance | Blade replacement | Lens and tube cleaning/replacement |

Note: Cutting speeds and consumable lifespans vary by manufacturer. It is advisable to compare the specific maintenance costs of blades versus laser tubes.

Versatility for cutting PVC, leather, coil, and carpet

A car mat business rarely cuts just one type of material. You might cut luxurious leather for a sedan one day and heavy-duty wire loop (coil) mats for an SUV the next. The oscillating knife head is designed to handle this variety without difficulty.

The core advantage lies in the high-frequency vibration. If you try to cut thick rubber with a static (non-moving) knife, the material creates friction. It grabs the blade. This can cause the material to drag or bunch up. The oscillating blade vibrates thousands of times per minute. This vibration breaks the surface tension and friction. It allows the blade to glide through thick, dense, or multi-layer materials smoothly.

Handling Multi-Layer Composites

Modern car mats are often “sandwiches” of different materials. A common example is the “5D” or “7D” mat. These usually consist of:

- PU Leather surface

- Sponge layer

- XPE foam core

- Anti-slip burr bottom

A standard rotary cutter might twist these layers. A drag knife might tear the leather surface. The oscillating knife cuts straight down through all four layers at once. It ensures the top layer matches the bottom layer perfectly. This precision is vital for fitting the complex floor curves of a car.

Plus, swapping materials doesn’t have to be a headache. You typically only need to change the specific blade type (e.g., a serrated blade for coil mats or a finer blade for leather) rather than the entire tool head. This flexibility keeps your production line moving efficiently.

Feature 2: Intelligent Nesting Software

How does intelligent nesting software directly improve profitability for car mat manufacturers?

Intelligent nesting software utilizes advanced algorithms to automatically arrange cutting patterns on raw material sheets in the most spatially efficient layout. By mathematically calculating the optimal rotation and placement of irregular shapes, this technology minimizes scrap waste and maximizes material yield, significantly reducing the cost per unit.

Optimizing material utilization to save costs

In the car mat industry, raw material is often your largest ongoing expense. Whether you use leather rolls, PVC, or expensive TPE sheets, every square inch counts. Manual layout is risky. Even an experienced worker creates gaps between patterns. They do this to avoid accidental overlap. These safety gaps result in wasted material that ends up in the trash.

Intelligent nesting software solves this problem mathematically. It treats the material sheet like a precise grid. The software takes the different shapes—driver mat, passenger mat, and rear tunnel cover—and rotates them to fit perfectly together. It works similarly to a workshop planner arranging tools on a pegboard to fit the most items in a limited space. However, the software does this in seconds rather than hours.

Industry Insight: Manual nesting typically achieves material utilization of around 75% to 80%. High-end nesting software can often push this utilization rate above 90%.

Think about your bottom line here. If your software increases utilization by just 10%, you effectively get one extra set of car mats for every ten sets you produce, without buying any extra material. This is pure profit added to your bottom line.

Manual vs. Intelligent Nesting Comparison

| Factor | Manual Layout | Intelligent Auto-Nesting |

|---|---|---|

| Spacing | Large gaps (safety margin) | Minimal gaps (often 1-3mm) |

| Time Required | 15–30 minutes per batch | 1–3 minutes per batch |

| Material Waste | High (large offcuts) | Low (mostly unusable scraps) |

| Consistency | Varies by worker skill | Consistent every time |

Note: Material saving percentages depend on the specific software algorithms and the geometry of the patterns. A demo using your specific files is often the best way to verify efficiency gains.

Automating complex cutting paths for speed

Efficiency is not just about where the shapes are placed. It is also about how the machine moves between those shapes. This is known as path optimization.

Without intelligent software, a cutting machine might act inefficiently. It might cut a shape on the left side of the table, travel all the way to the right to cut another, and then go back to the left. This non-cutting movement is called “air travel” or “idle movement.” It wastes valuable production time.

Smart software calculates the shortest possible route for the cutting head. It connects the end point of one cut to the nearest start point of the next cut. Imagine a CNC drilling operation where the machine drills holes in a straight line rather than jumping randomly across the metal plate. The nesting software applies this same logic to your car mats.

Taking it a step further, advanced software handles common line cutting. If two mats have a straight edge, the software places them exactly side-by-side. The knife cuts that single line once, and it separates both pieces. This technique reduces the total cutting distance and time by up to 30%.

Key Software Capabilities to Check:

- Gap Control: Ability to set precise spacing between parts.

- Defect Avoidance: Can the software route around marked flaws in the leather?

- Format Compatibility: Does it accept PLT, DXF, and AI files easily?

By automating these complex calculations, the machine spends more time cutting and less time moving through the air. Therefore, your daily output increases significantly.

Feature 3: Partitioned Vacuum Adsorption Platform

How does a vacuum table prevent material movement during the aggressive cutting process?

A partitioned vacuum adsorption platform employs high-power airflow to securely clamp raw materials against the machine bed. By dividing the worktable into independent control zones, the system concentrates suction force only where the material is present, ensuring maximum holding pressure for precise cutting without mechanical clamps.

Securing materials firmly during high-speed operation

When the oscillating knife moves through a car mat, it exerts significant lateral force. This side-to-side motion creates drag. If the material is not secured perfectly, it will shift. Ever tried cutting a material that won’t stay put? Even a movement of just one millimeter can ruin the alignment of a car mat set. This creates waste and delays production.

Mechanical clamps are not suitable for this task. They cover the edges of the material, which restricts where the knife can cut. Instead, the industry relies on vacuum adsorption. This works similarly to a vacuum chuck used in CNC metal milling to hold thin plates. The air pulls the material down uniformly across its entire surface.

But here is the catch with standard tables: If your material only covers half the table, the air escapes through the open holes on the empty side. This causes a massive loss of pressure.

The solution is a Partitioned (Zoned) Vacuum System.

The table is divided into multiple square sections, typically 6 to 8 zones depending on the table size. You can open or close the valves for each zone electronically. When you cut a small set of mats, you activate only the zones under the material. This concentrates 100% of the pump’s power exactly where you need it.

Impact of Vacuum Zoning on Cutting Stability

| Feature | Standard Vacuum Table | Partitioned Vacuum Table |

|---|---|---|

| Suction Power | Diluted across the whole bed | Concentrated on the workpiece |

| Material Hold | Weaker on small pieces | Strong on all sizes |

| Energy Efficiency | Low (wastes air flow) | High (optimizes air flow) |

| Risk of Shift | Moderate | Minimal |

Note: The number of vacuum zones and pump power typically ranges from 7.5kW to 9.0kW depending on the machine model. Ensure the specifications match your primary material type.

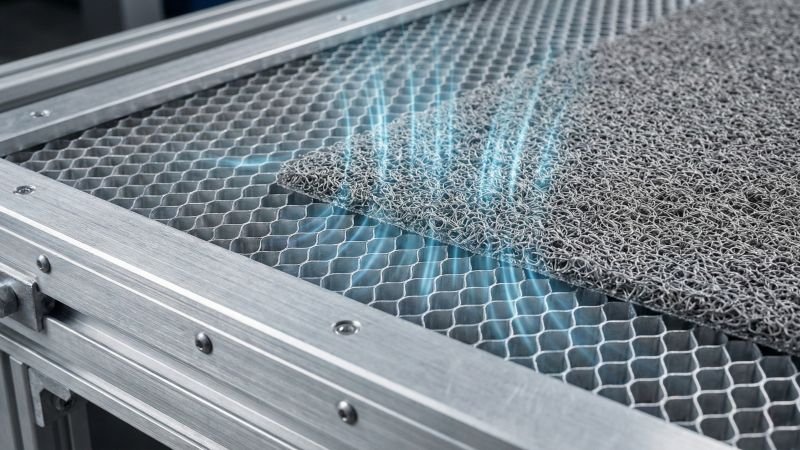

Handling uneven surfaces of coil or leather mats

Car mat materials rarely arrive perfectly flat. They usually come in large rolls. Because they have been rolled up for storage, the material has “memory.” It wants to curl back up when you unroll it.

If the material curls or ripples on the table, the distance between the knife tip and the table surface changes. This leads to incomplete cuts. The blade might cut through the top layer but fail to cut the bottom backing.

The vacuum platform solves this by forcibly flattening the material. The atmospheric pressure pushes the curled leather or rubber flat against the bed. This creates a uniform surface for the knife.

Dealing with Porous Materials (Wire Loop/Coil)

Wire loop (coil) mats present a unique challenge. They are full of holes. Air passes right through them, which breaks the vacuum seal. The machine cannot hold the mat down if air flows through it freely.

To solve this, operators use a technique common in the composites industry. They place a thin, airtight plastic film (PE film) over the coil mat.

- Placement: The coil mat is placed on the table.

- Covering: The plastic film covers the mat.

- Adsorption: The vacuum pulls the plastic film down.

- Result: The film presses the coil mat firmly against the table.

This technique ensures that even “breathable” materials remain rigid during the cutting process. It guarantees that the knife cuts vertical edges cleanly, rather than pushing the soft material sideways.

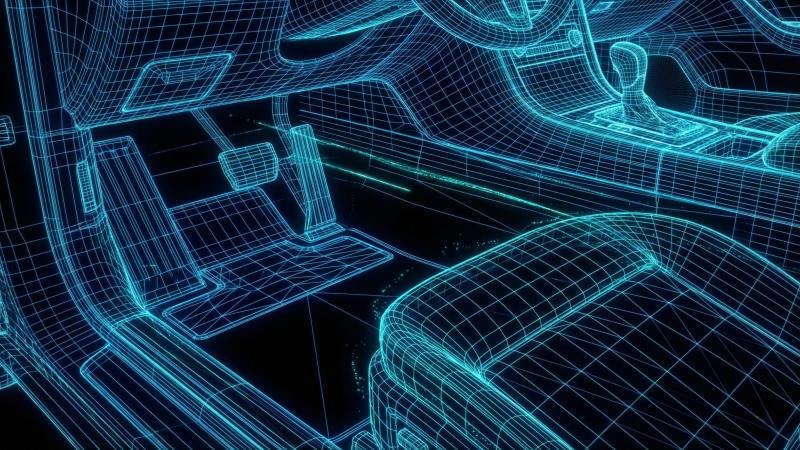

Feature 4: Integrated Vehicle Model Database

How does a pre-loaded vehicle model database transform the efficiency of a car mat production business?

An integrated vehicle model database provides immediate access to digital patterns for thousands of car makes and models, eliminating the need for manual measurement and design. By connecting the cutting machine directly to a vast library of ready-to-cut files, manufacturers can instantly retrieve precise floor dimensions for specific vehicles, reducing pre-production lead time from hours to mere seconds.

Accessing accurate patterns for thousands of car models

How much time is your team wasting on manual measurements? The biggest bottleneck in traditional car mat manufacturing is obtaining the correct dimensions. In the past, if a customer brought in a vehicle that you did not have a pattern for, you had to manually measure the floor.

This manual process typically involved using paper or tape to create a physical template inside the car. This method is slow, messy, and prone to human error. If your hand shakes while tracing a curve, the final mat will not fit.

A modern cutter equipped with an integrated database solves this. The manufacturer of the machine usually provides a comprehensive digital library. This library contains 2D vector files for thousands of vehicles, ranging from common sedans to luxury SUVs. These patterns are created using 3D laser scanning technology. Engineers scan the actual car floor to capture every curve, seat track, and pedal position with sub-millimeter accuracy.

Industry Fact: A professional database typically covers 95% of mainstream vehicles on the road, including different model years (e.g., a 2018 Honda Civic vs. a 2022 Honda Civic).

Comparison: Manual Patterning vs. Digital Database

| Aspect | Manual Paper Patterning | Digital Database Access |

|---|---|---|

| Accuracy | High risk of human error | Exact digital replica (3D Scanned) |

| Time to Acquire | 1–2 hours per vehicle | 5–10 seconds (Search & Load) |

| Storage | Physical storage required | Digital cloud or local drive |

| Updates | Impossible without re-measuring | Constant updates for new cars |

Note: Database coverage and update policies vary significantly by supplier. Some manufacturers charge an annual subscription fee for new car models, while others offer lifetime free updates. Always clarify these terms before purchase.

Simplifying the workflow for custom orders

The car mat business is often a “made-to-order” industry. Customers rarely buy standard sizes; they want a perfect fit for their specific vehicle. The database changes your workflow from a craftsmanship task to a digital selection process.

Imagine a customer requests mats for a Right-Hand Drive (RHD) BMW X5. Without a database, you would need that exact car present in your shop to measure it. With the database, you simply type “BMW X5 RHD” into the software. The correct file appears immediately. You can then send this file directly to the cutter.

This capability allows you to accept orders for cars that are not physically in your workshop. You can sell mats online for customers across the country because you already possess the digital data for their vehicles.

But you aren’t stuck with stock sizes. The database allows for rapid customization. Once you load the standard pattern, the software allows you to modify it slightly before cutting.

- High Walls: You can extend the edges to create “3D” mats that cover the side walls of the footwell.

- Pedal Clearance: You can adjust the cutout area around the gas pedal if the customer has aftermarket pedals.

- Logo Integration: You can mark positions for logos or heel pads digitally.

This process is similar to loading a standard blueprint in CAD (Computer-Aided Design) software and making a quick modification, rather than drawing the entire blueprint from scratch. It ensures that your response time to customer orders is fast and professional.

Feature 5: Automatic Feeding System

What is the primary advantage of an automatic feeding system for high-volume car mat production?

An automatic feeding system consists of a motorized rolling stand and a conveyor belt table that advances raw material into the cutting zone automatically. By synchronizing the movement of the material with the cutting files, this system eliminates the need to manually load individual sheets, allowing for the continuous processing of heavy rolls and significantly increasing daily output.

Enabling continuous cutting for roll materials

Standard flatbed cutters have a fixed table size. For example, if your table is 2.5 meters long, you can only cut a piece of material that fits within that 2.5 meters. To cut the next piece, the machine must stop. You must remove the cut parts and lay down a new sheet. This is known as “static cutting.”

The automatic feeding system changes the machine into a “conveyor” system. The table surface is not a solid metal plate. Instead, it is a high-durability felt belt that loops around the machine, similar to the belt on a sanding machine.

When the machine finishes cutting the current section, the felt belt moves forward. It pulls fresh material from the roll at the back of the machine into the cutting area. Simultaneously, it pushes the finished cut parts off the front of the table for collection.

This unlocks “Infinite Length” Cutting.

If you need to cut a floor mat for a large bus or a limousine that is 5 meters long, a static table cannot do it. However, with an automatic feeding system, the machine cuts the first half, advances the material, and then cuts the second half seamlessly. The software stitches the two sections together perfectly.

Industry Note: This feature is essential for materials like PVC coil (wire loop) and needle-punch carpet, which are almost always supplied in long, heavy rolls (usually 10 to 20 meters in length).

Reducing manual labor and material loading time

Handling raw materials for car mats is physically demanding work. A standard roll of heavy-duty PVC or rubber car mat material can weigh between 50kg and 80kg (110–175 lbs).

Let’s be real: handling these heavy rolls manually is a nightmare. Without an automatic feeder, two workers are often required to lift these heavy rolls onto the table. They must unroll the material, align it manually, and smooth out any wrinkles. This process takes time and physical energy. As the day progresses, workers get tired, and their loading speed decreases.

The automatic feeding system includes a heavy-duty unwinding rack. You simply load the roll onto the rack once using a forklift or a lift cart. The machine takes over from there. A sensor detects when the material is tight and rotates the roller to release more material. This prevents the material from stretching or distorting before it reaches the cutter.

Labor Efficiency Comparison

| Task | Manual Static Table | Automatic Conveyor System |

|---|---|---|

| Loading Process | Stop machine, lift sheet, align manually | Continuous feed from roll |

| Operators Required | 1 operator for cutting, 1 helper for loading | 1 operator handles everything |

| Downtime | 3–5 minutes between every sheet | Zero (continuous operation) |

| Physical Strain | High (constant lifting) | Low (supervisory role) |

Note: The weight capacity of feeding systems varies by manufacturer. Some lightweight feeders only support 100kg, while heavy-duty industrial versions support up to 500kg.

Evaluating Build Quality and Core Components

Why is the structural integrity of the machine just as important as the cutting technology itself?

The build quality of a car mat cutter, specifically the frame rigidity and motion system, directly dictates the machine’s lifespan and cutting precision. A heavy-duty welded steel frame absorbs the vibrations generated during high-speed cutting, while industrial-grade servo motors and guide rails ensure that the machine maintains sub-millimeter accuracy without mechanical drift over years of continuous operation.

Importance of a heavy-duty welded steel frame

When a digital cutter slices through thick PVC or leather, the cutting head changes direction rapidly. These sudden stops and starts create significant physical force. If the machine frame is light or bolted together from thin aluminum, it will shake.

Vibration is the enemy of precision. Think of a carpenter working on a flimsy folding table versus a heavy solid wood workbench. If the table shakes, the saw cuts crooked. The same applies here. If the machine frame vibrates, you will see jagged lines on the edges of your car mats.

The Role of Stress Relief (Annealing)

A high-quality machine frame is not just welded; it is treated. When steel is welded, the heat creates internal stress. Over time, this stress can cause the metal to twist or warp naturally. To prevent this, professional manufacturers use a process called High-Temperature Annealing.

- The welded frame is placed in a giant oven.

- It is heated to high temperatures (often around 600°C).

- It cools down slowly.

- This “relaxes” the steel, ensuring it stays perfectly straight for 10 or 20 years.

Industry Warning: Cheaper machines often skip the annealing process to save electricity costs. These machines may cut well for the first month, but the frame may distort after a year, causing the gantry to become misaligned.

Frame Specifications to Check

| Feature | Professional Industrial Standard | Economy/Hobby Grade |

|---|---|---|

| Structure Type | Integrated Welded Steel Tube | Bolted Aluminum Profiles |

| Steel Thickness | 6mm – 10mm (Heavy Wall) | 3mm – 4mm (Thin Wall) |

| Weight | Heavy (1000kg+) | Light (Under 600kg) |

| Stability | No vibration at high speed | Visible shaking at high speed |

Note: Steel thickness and overall machine weight will vary based on the working area size. Professional models are significantly heavier to absorb kinetic energy.

Selecting reliable servo motors and guide rails

If the frame is the skeleton of the machine, the motors and rails are the muscles. They determine how fast and how accurately the knife moves.

Servo Motors vs. Stepper Motors

For commercial car mat production, you should prioritize AC Servo Motors.

- Stepper Motors: These are cheaper but operate on an “open loop” system. The computer tells the motor to move, but the motor does not reply. If the knife hits a hard spot in a rubber mat, the motor might skip a step. The machine doesn’t know it missed a step, and the rest of the cut will be wrong.

- Servo Motors: These use a “closed loop” system with an encoder. The motor constantly talks back to the computer. If the resistance increases (like cutting through thick carpet), the servo motor instantly applies more power to correct the position. This ensures the cut line matches the design file exactly.

Linear Guide Rails

The cutting gantry slides on rails. You should look for reputable brands of linear square guide rails (such as Hiwin or PMI). These rails use recirculating ball bearings to carry heavy loads with very little friction.

Avoid machines that use simple round rails or wheel-on-rail systems for the main axis. In a dusty environment—and cutting car mats creates dust—round rails can wear out unevenly. Square linear guides are designed with seals to keep dust out of the bearings, ensuring smooth movement for years.

Rack and Pinion Transmission

For the X and Y axes, most industrial cutters use a helical rack and pinion system rather than a ball screw. A ball screw is precise but slow. A helical rack allows for high-speed acceleration without losing accuracy. This is crucial when you need to produce 50 or 100 sets of mats per day.

Partnering with the Right Manufacturer

Why is the level of post-purchase support often more critical than the initial price of the machine?

A partnership with a manufacturer that offers comprehensive technical support and transparent warranty terms is essential for minimizing costly production downtime. Reliable suppliers provide immediate remote diagnostics, readily available spare parts, and ongoing software training, ensuring that your cutting equipment remains operational and profitable long after the initial installation.

Verifying warranty terms and technical support

Buying a car mat cutter is a significant investment. However, the relationship with the seller does not end when the machine arrives at your factory. In fact, that is when the real partnership begins. Machines are complex tools. They have moving parts, electronics, and software that must all work together. If one part fails, your production stops.

This is why you need to look closely at the warranty. A standard warranty usually covers the machine for one or two years. But you need to know exactly what is covered.

Distinguishing Core Parts from Consumables

In the cutting industry, not all parts have the same warranty.

- Core Components: Items like the servo motor, the control board, and the guide rails should have a long warranty (typically 1–2 years). These parts should not fail under normal use.

- Consumables: Items like the oscillating knife blades, the vacuum table felt, and the knife holder are expected to wear out. They are usually not covered by the warranty.

Industry Insight: “The most expensive cost in manufacturing is not the part that breaks, but the time you spend waiting for a replacement while your orders pile up.”

The Necessity of Remote Diagnostics

When a problem occurs, you cannot afford to wait weeks for a technician to fly to your location. You need immediate answers. Modern support relies on Remote Desktop Access.

Reliable manufacturers use tools like TeamViewer or AnyDesk. These tools allow their engineers to connect directly to your machine’s computer over the internet. They can check the software settings, update parameters, and diagnose error codes instantly. It is similar to an IT specialist fixing your computer from another building. Without this capability, you are left guessing what went wrong.

Support Service Comparison

| Feature | Standard/Basic Vendor | Premium Manufacturer Support |

|---|---|---|

| Response Time | 24–48 hours (Email only) | 1–2 hours (Instant Chat/Call) |

| Troubleshooting | Sends a PDF manual | Connects via Video/Remote Desktop |

| Language | Potential barrier | Fluent English support team |

| Spare Parts | Ships from overseas (slow) | Quick dispatch via DHL/FedEx |

Note: Time zone differences can affect response times. Verifying the support team’s operating hours relative to your location is recommended.

Contact Us for a personalized machine recommendation

Every car mat business is unique. A small shop making custom luxury leather mats has different needs than a large factory producing thousands of PVC coil mats per day. Therefore, buying a “one size fits all” machine is rarely the best strategy.

You need a solution tailored to your specific production volume and material types. We understand that choosing the right features—like the specific knife power, the table size, or the number of vacuum zones—can be overwhelming.

We are here to help you navigate these choices.

By analyzing your current workflow and future goals, we can recommend the exact configuration that maximizes your Return on Investment (ROI). We can help you answer critical questions:

- Do you need a conveyor system for roll materials?

- Is your primary material dense rubber or soft carpet?

- Do you require a specific voltage for your facility?

Take the Next Step

Do not leave your production efficiency to chance. Contact us today to speak with a specialist. Let us help you build the perfect cutting solution for your business.